English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

What Innovations Are Improving Glass Shipping Pad Performance?

2025-06-30

The high breakage rate of glass during transportation has always been a pain point in the logistics industry. The new generation of Glass Shipping Pads recently launched by Raybone, through material innovation and structural optimization, has reduced the transportation breakage rate to less than 0.3%, becoming the "invisible guardian" in the transportation field of high-end glass products and precision instruments.

Raybone has specifically developed three types of high-performance transport pads to precisely match different transportation scenarios

1.Cork-Glass-Shipping-Pads : It uses natural cork as the base material and is covered with a high-density fiber layer on the surface. It not only retains the cushioning and energy absorption characteristics of cork but also enhances wear resistance through the fiber layer. A certain photovoltaic enterprise's actual measurement shows that when using this gasket to transport photovoltaic glass, the corner damage rate decreases by 67%.

2.EVA- rubber-Glass-Shipping -Pads- With-Adhesive : Made of food-grade EVA rubber with a built-in high-strength Adhesive backing, it can closely adhere to the Glass surface and prevent displacement during transportation jolts. A high-end furniture brand has reported that this product has reduced the scratch rate of curved glass during transportation to zero.

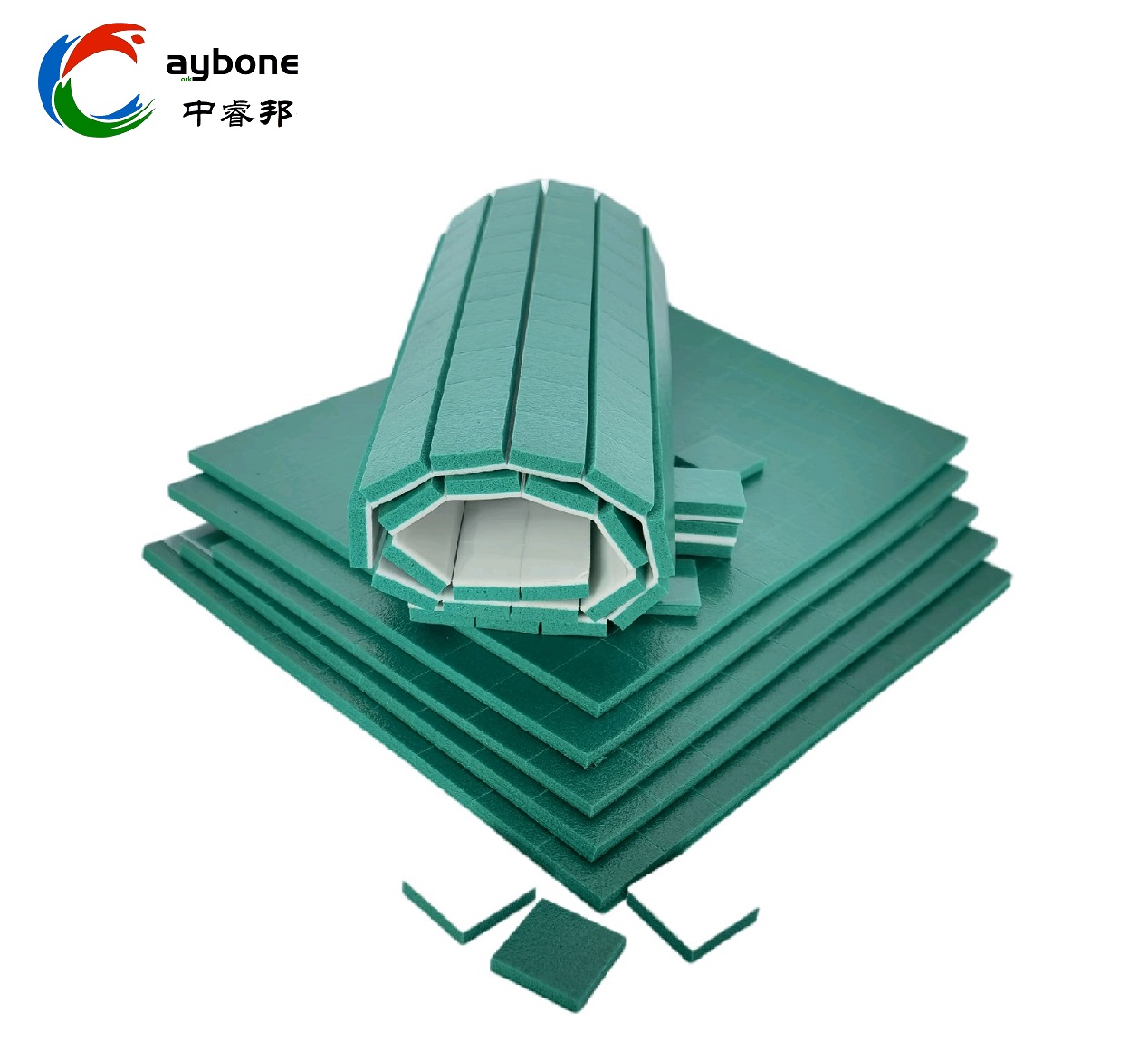

3.PVC-Glass-Shipping-Pads-with-Cling-Foam : By wrapping closed-cell foam with a PVC shell, it achieves the triple functions of "buffering + moisture-proofing + silence". Tests conducted by a certain automotive glass supplier show that in a low-temperature environment of -20℃, this gasket can still maintain elasticity and prevent stress cracks in the glass due to cold shrinkage.

We once received the transport pad returned by the customer, which was covered with scratches, but the glass was intact. The quality inspection manager of Raybone smiled and said, "This convinces us that true protection is' sacrificing oneself to preserve the goods'."

The technological leap from "passive buffering" to "active protection"

Traditional transport pads mostly rely on material thickness to achieve buffering, while Raybone achieves performance breakthroughs through microstructure design. For example, by implanting honeycomb-shaped pores in the cork composite pad, the efficiency of impact force dispersion can be increased by 40%. The "gradient adhesion" technology is adopted in the self-adhesive EVA pad to ensure a firm initial adhesion and leave no residue when disassembled.

What is more notable is that Raybone integrates the intelligent monitoring module into the PVC foam pad. With the built-in pressure sensor, customers can track the vibration data during transportation in real time and issue early warnings of potential risks. A customer optimized the truck suspension system based on our data report, reducing the cost of a single trip by 12%. The technical director disclosed.

Raybone redefines the standards for "fragile goods transportation"

In the past, glass transport pads were "consumables"; In the future, it should be "the core component of the security system". The general manager of Raybone stated at a recent industry summit, "We are developing degradable cork composite materials and plan to launch 'zero-pollution transport pads' next year, making environmental protection as important as protecting goods."

At present, Raybone has established cooperation with more than 200 glass deep processing enterprises worldwide. Its products have passed the ISO 14001 environmental management system certification and obtained the "Grade A Impact Resistance performance" evaluation of TUV Rheinland. With the explosive growth of industries such as smart home and new energy vehicles, the transportation demand for high-end glass products has been continuously increasing. Raybone is seizing the "precision transportation" market at an annual capacity expansion rate of 30%.

From the thickness of a single gasket to the safety of the entire transportation system, Raybone has proved with innovation that true protection begins with an obsession with details. Just as its brand slogan says: "Let every piece of glass safely reach where it should be."